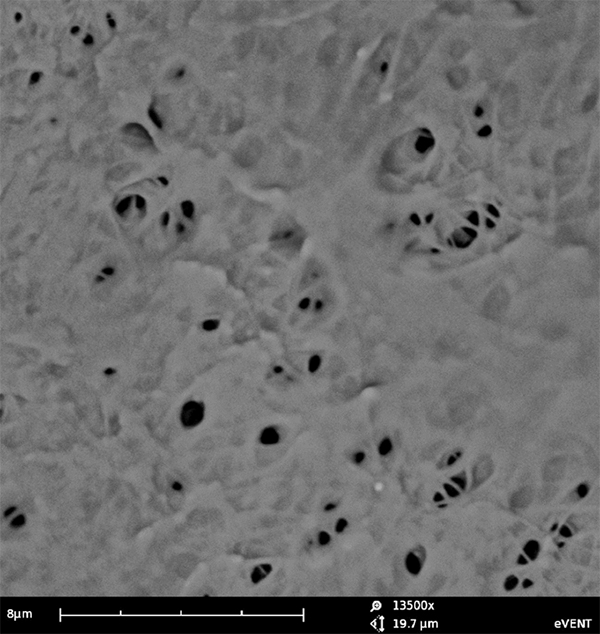

Existing technology uses a wet chemistry process to coat the PTFE membrane and render it oleophobic. This process leaves a physical coating of oleophobic material on the surface, blocks off many of the pores of the membrane, and adds a level of stiffness/stability to the membrane, making it less prone to lamination difficulties.

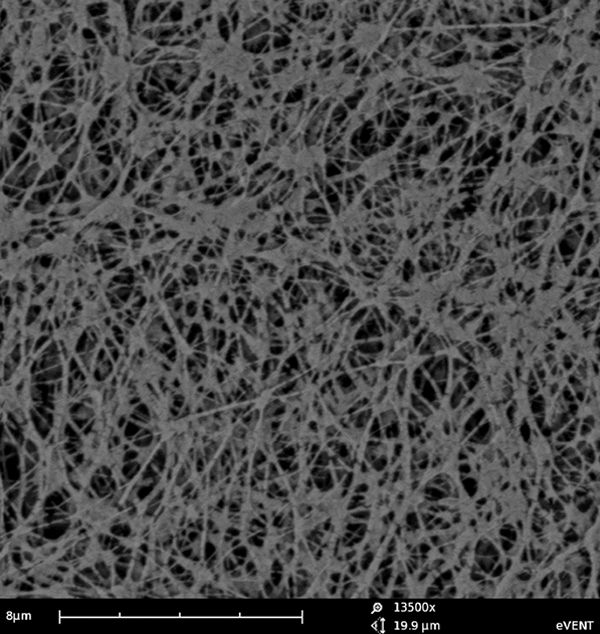

New technology uses a dry plasma process that penetrates throughout the entire thickness of the membrane and chemically modifies the surface of the PTFE. The pore size and structure are not affected by this treatment, and the flexibility of the membrane is equivalent to that of untreated membrane. The physical properties of the treated film are very similar to that of untreated film.

|

Side A competitor – 13,500x |

Side B SST – 13,500x |

SWOT Analysis

Strengths

- 0.2, 0.45, 0.9 and 1.5 um, meet or exceed market expectations

- Treated products consistently meet oil 8

- Laminates process well

- Ability to perform failure analysis and troubleshoot

- Lead times excellent

Weaknesses

- Polyester backed products weep under low pressure

- No membranes under 0.2 um (0.05um in development)

- 090 and 150 don’t match up with competitive offerings

- No steam sterlizable offering