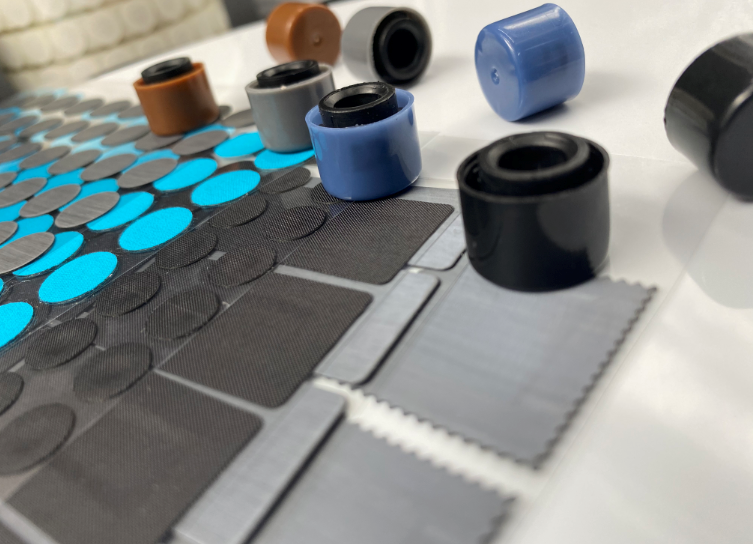

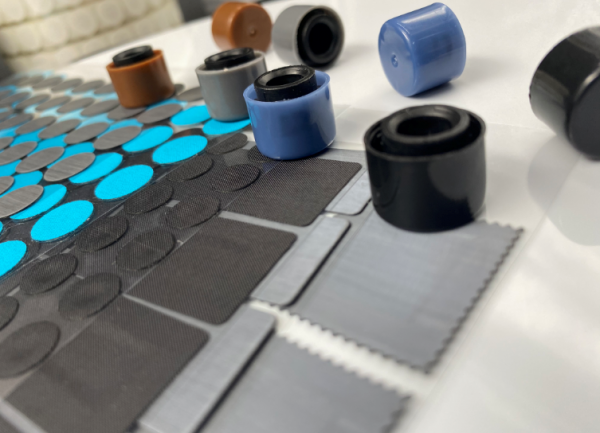

SST-Porous ®Adhesive Eptfe Waterproof Breathable Vents Membrane BD 04 series –(typical applications: Car headlights, Gas electrochemical sensors, Pressure sensors, Sweeping robots, etc.)

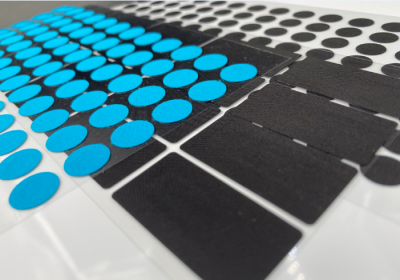

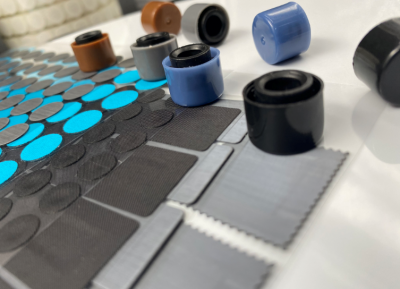

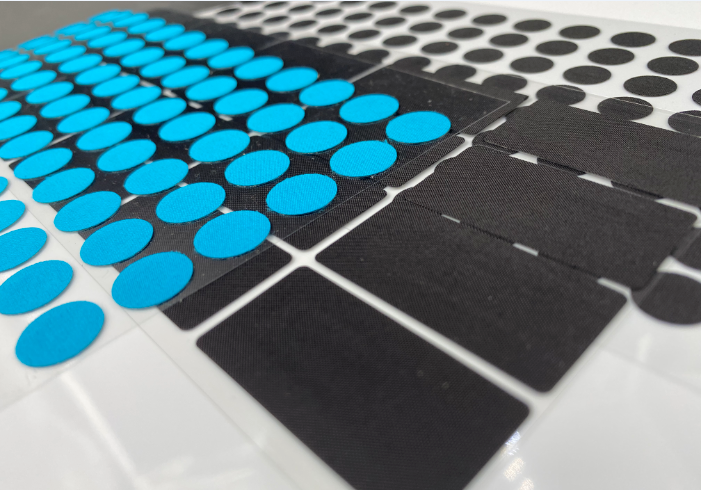

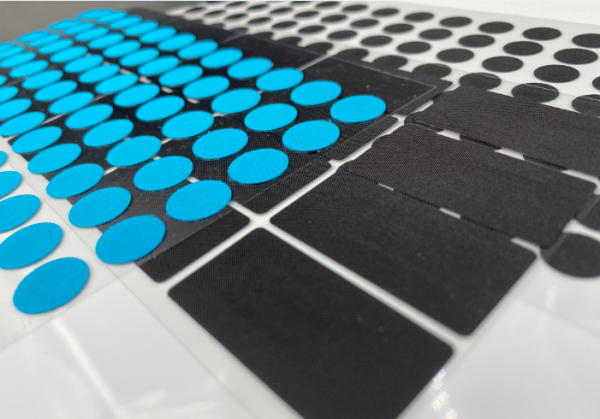

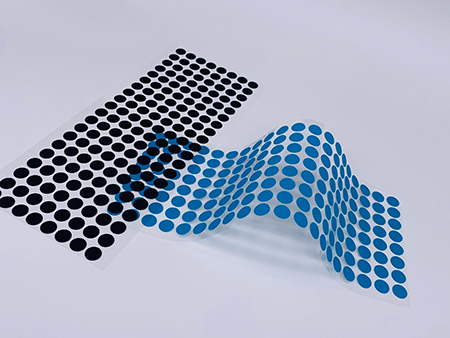

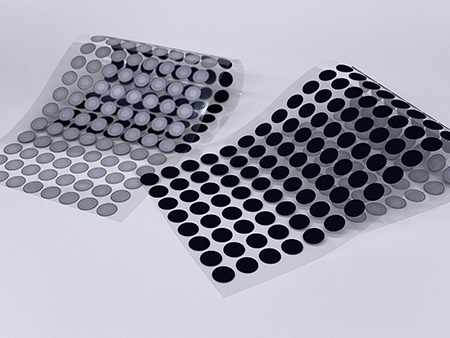

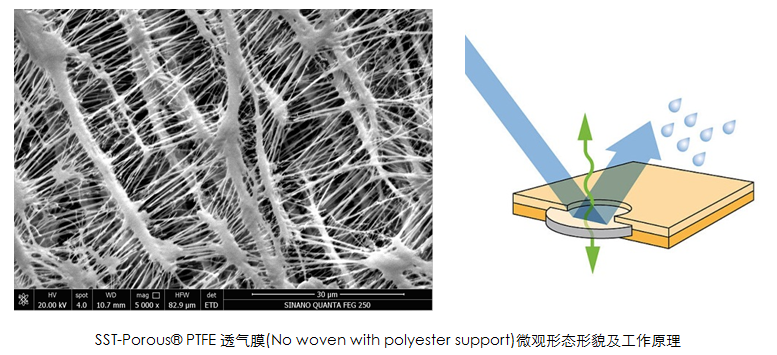

SST-Porous ® Black adhesive vents BD 04 series, made by SST porous ® ePTFE membrane which compounded with polyester or nylon fabric, and then combined with acrylic adhesive. The BD 04 series adhesive vents are formed with different color choices to reduce the abrupt feeling of breathable membrane and plastic parts.

What is SST-Porous® adhesive & BD 04 series waterproof breather vents membrane?

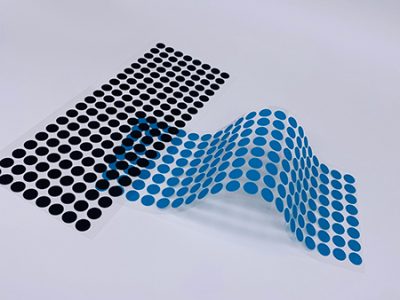

SST-Porous®adhesive &BD 04 series breathable vents, reseach and developed by SST independently. made of SST-Porous® PTFE membrane and base material of PET or Nylon fabric,formed through a special composite process. SST-Porous® BD 04 series, vents still maintains a high permeability and average pore diameter, but not easily stratified. Color blue and Black for your choice.

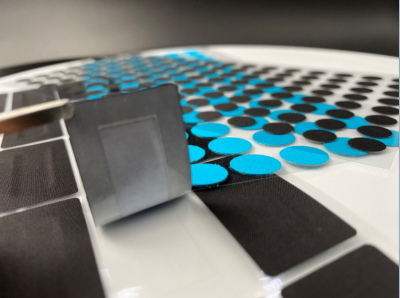

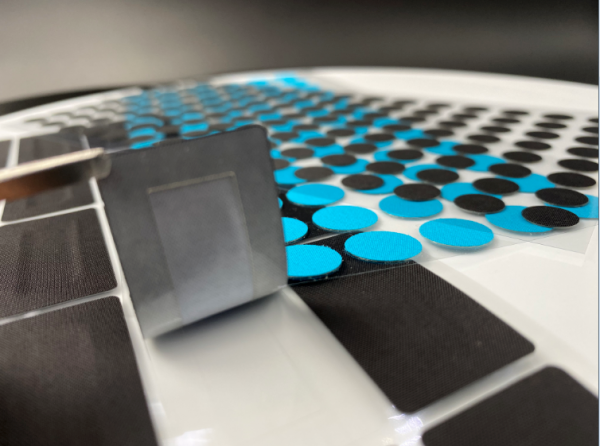

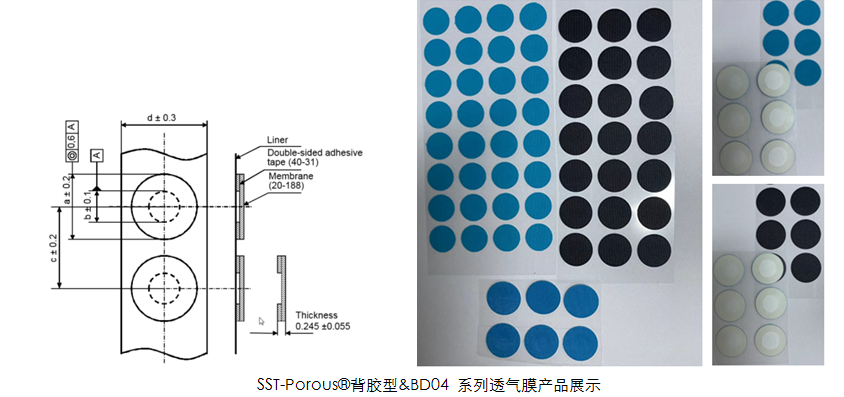

SST-Porous® BD 04 series, The breathable membrane and acrylic adhesive are precisely processed and combined to form a adhesive breathable vent product.

SST-Porous® adhesive &BD04 series, permeable membrane vents is waterproof, dustproof but breathable, equalize pressure (pressure compensation), be fixed to the surface of the electronic component housing either automatically or manually.

SST-Porous®Adhesive &BD04 series breather vents processing

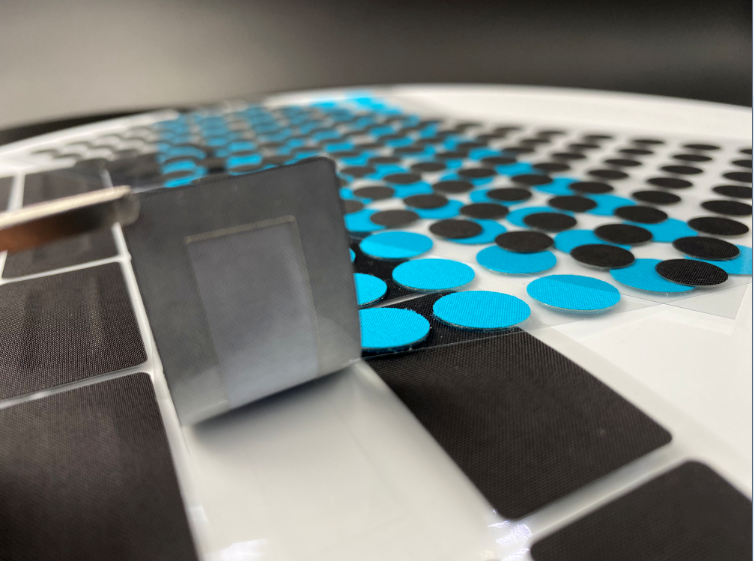

SST-Porous® PTFE breather membrane, through precision die cutting process, die cut the adhesive membrane to different sizes according to the actual working conditions or customer specifications, made into SST bulk production for delivery.

SST-Porous®Adhesive &BD04 series vents ‘s feature and characteristic

1、characteristic

※ Extend the service life of electronic equipments, quickly pressure equalization to reduce the stress on the sealing ring of the equipment housing

※ Reliable protection,SST-Porous® PTFE Hydrophobic and Oleophbic breather vents could prevent the entry of water, salt, corrosive liquids and particulate etc

※ Improve durablity, improve the durability of sealed enclousures by following the industry standards

※ Flexible design, installation and maintenance more convenient

※ Wide range of vents with high airflow, high temperature stablity and well-matched strong adhesive to housing surface

※ Outstanding technic expertise, rich technical knowledge accumulated by SST engineering department provides the most professional technical service and support for global terminal applications

2、Specification and dimension

|

\ |

Item | Backing Material | Spec | Typical airflow

ml/min@7kPA |

WEP,

kPA,50seconds |

Membrane type | IP rate | Temperature | Color

visible side |

| 1 |

BD 04100100-Lake Blue |

Nylon | OD: 12.7

ID: 7.1 |

>500 | >200 | (e-PTFE) | IP67,IP68 | -30~120℃ | Blue |

| 2 | BD 04100100-Black | Polyester fabric | OD: 12.7

ID: 7.1 |

>500 | >200 | IP67,IP68 | -30~120℃ |

Black |

|

Explaination:※ Specification are measured by the backing material of lake blue nylon fabric and black polyester fabric, if other sizes or backing material required, please contact our engineer※ Available color: Lake blue, Black |

|||||||||

[Remarks]

※ If you have quiry on dimesion, please contact us spider_e-ptfe@spider-amoy.com;

※ The above data are all sample measurements, so the actual performance can not be guaranteed, and the technical data may change;

※ Ingress Protection rate per IEC 529–598

[Warning]

※ Do not attempt to burn SST-Porous® plastic & snap fit vents, as material PTFE in the structure may produce toxic gases when burned

※ All statements and technical information contained herein are based on tests that we believe to be reliable and describe only general attributes and therefore cannot guarantee the safety of each application by the user. For security reasons, the user should determine their suitability for the intended use

※ The User is solely responsible for all damages that may be directly or indirectly caused by the use of the Products and all descriptions herein are based on currently available data and information

Typical application

- (1) Automotive Vents

※ Headlamps

※ Tail lamps

※ Turning signal lamps

※ Deep car signal light - (2) Outdoor Electronics Vents

※ Gas electrochemical sensor

※ Pressure sensor

※ Sweeping robot

Handling and Installation guide

SST-Porous® adhesive & BD04 series breather vents, it is a high-tech products that need professional final-processing.

Please contact us when planning to enter your manufacturing process, not all final-processings are compatible with this product. We will be pleased to offer our expertise in this field to you.

-

Installation Surface

Recommended Surface roughness:Rz<10µm(max:Rz<16μm)。

Mounting surfaces should be dry and clean and free of oils, particles, release agent and other contaminants. the loose oxide layer on the surface will reduce the durability.

-

Recommeded cleaning

Grease free solvent, like heptane, isp[ropanol or alcohol.

In case of incompatibility, select another cleaning agent for the application surface.

-

Pressure sensitive adhesive operation guide

Press fit——suitable for semi-automatic installation

To achieve excellent press fit design and to obtain appropriate pressure,please follow the general recommendations as below:

- Pressing head shall be made by soft rubber of uniform thickness and at least 0 mm thickness(Shore hardness A 20 — 40 )

- The pressing head shall be vertical to the mounting surface and located in a position to apply pressure to the target/guard ring

- Accoding to the size of adhesive area, apply uniform pressure 7 bar recommended to the adhesive ring to seal device or housing. The pressure on the surface of the pressing head should be appropriate to avoid pressing into the venting area

- After pressing, the dwell time should exceed 5 seconds

- Allow at least 24 hours dwell time before using or testing the vent

- The above steps are very important to ensure the vent sealed on the housing firmly

Press fit——suitable for manual installation

- Ensure the entire adhesive ring is attached to the surface of the device or housing

- Apply light finger pressure to the adhesive ring at least two circles to assure the seal to the device or housing, be carefull not touch the central part of the vent

- Allow at least 24 hours dwell time before using or testing the vent

- The above steps are very important to ensure the vent sealed on the housing firmly

E-mail:weitaiyan@spider-amoy.com

WhatsApp:18695679892