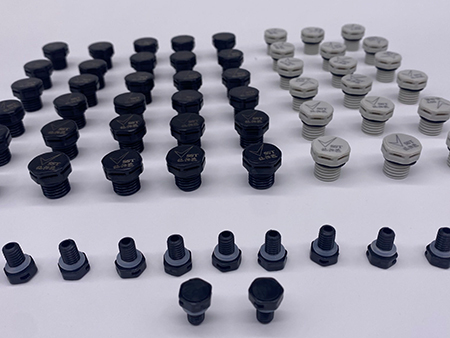

SST-Porous®Plastic waterproof breathable screw vent plug –(typical application:Electric motor control, converter/inverter, charger, distribution module, electric traction motor, battery pack/box, etc)

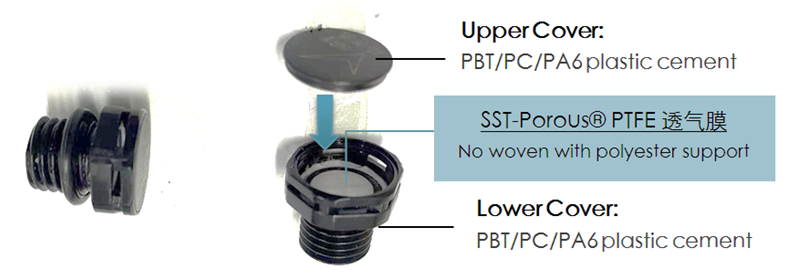

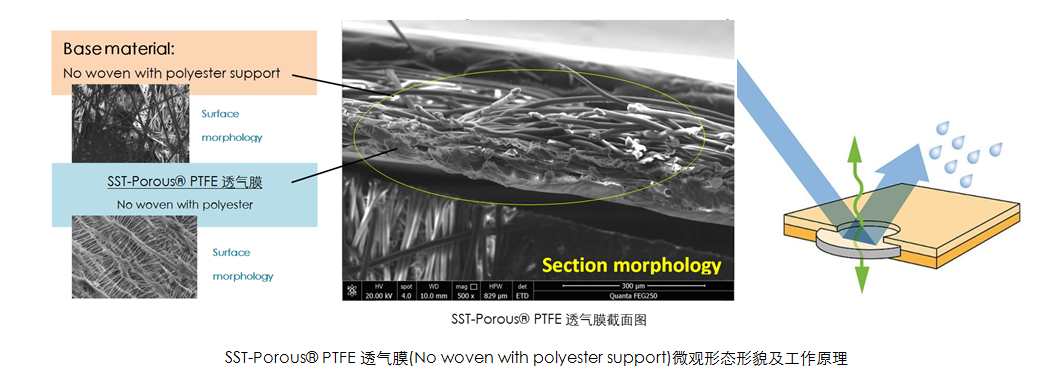

SST-Porous®Plastic waterproof breathable screw vent plug, made from SST-Porous® e-PTFE membrane(No woven with polyester support) and designed & completed poly covers, combined together through thermal melt or ultrasonic welding process. The robust entire components results in new functionality and characteristics, reducing costs, and enables one-click installation.

What is SST-Porous®Plastic waterproof breathable screw vent plug?

SST-Porous® Plastic waterproof breathable screw vent plug, reseach & developed by SST independently, formed by SST-Porous® ePTFE membrane(No woven with polyester support) and designed & completed poly lower cover(PBT/PC/PA6 etc) through thermal melt or ultrasonic welding process, then put Upper Cover. The complex components could protect ePTFE membrane from puncturing, collision and other damages and so improve the vents’s service life, safety and reliability and durability. The robust entire components result in new functionality and characteristics, reducing costs, and enable one-click installation.

Typical Characteristics:

* Excellent waterproof、permeablity、hydrophobic、Oleophobic

* Integrates easily into your device for quick assembly

SST-Porous® Plastic & Srew In protective vents’s features & characterisic

1、Characteristics

※ Equalize pressure quickly to extend service life, manage condensation effectively, and reduce the design complexity, weight, and cost of the components

※ Provides reliable protection against water and other liquids for sensitive electronic equipment

※Effective repelling of contaminants such as dirt, dust or salt

※ Integrate easily: Fast and simple integration ensures lasting performance for any application

※ More safety: Apply rugged threaded construction and durable O-ring, to protect the inside waterproof and breathable membrane reliably

※ Reliable Protection: SST Porous® Tech. breathable membranes prevent entry of contaminants even immersed in water

※ Robust and Durable: High strength, resistance to harsh environment, specially designed for chemical resistance, Uv resistant linearity, temperature resistance and hydrolysis stability

※ Qualified product: Durable automotive grade glass filled PBT plastic with 100% quality control, type of M6&M12 protective vents are fully traceable.

※Oleophobic vent meet oil repellency ratings up to 8 per AATCC Spec 118-1992, Hydrophobic vents meet water repellency ratings up to IP69K

2、Specification

|

No |

Item | material | Spec | Typical aireflow

ml/min@7kPA |

WEP,

kPA,50sec |

Membrane material | IP rate | Temperature |

Color |

|

1 |

BD TF-PC-45-12150 | PC | M12*1.5 | >500 | >200 | e-PTFE | IP65,IP66,IP68 | -30~140℃ | Nature |

|

2 |

BD TF-PA-45-12150 | PA | M12*1.5 | >500 |

>200 |

IP65,IP66,IP68 |

-30~140℃ |

Nature |

|

| 3 | BD TF-PA-100-12150 | PA | M12*1.5 | >1500 | >100 | IP65,IP66,IP67 | -30~140℃ |

Nature |

[Remarks]

※ If you have any query on size, please contact us spider_e-ptfe@spider-amoy.com;

※ Above data are all sample measurements, so the actual performance can not be guaranteed, and the technical data may change;

※ IP rate per IEC 529–598

[Warning]

※ Do not attempt to burn SST-Porous® Plastic & Srew In Protective Vents, as material PTFE in the structure may produce toxic gases when burned

※ All statements and technical information contained herein are based on tests that we believe to be reliable and describe only general attributes and therefore cannot guarantee the safety of each application by the user. For security reasons, the user should determine their suitability for the intended use

※ The User is solely responsible for all damages that may be directly or indirectly caused by the use of the Products and all descriptions herein are based on currently available data and information

Typical Application

- Electric control

- battery cells

- distribution boxes

- outdoor electronic equipment

- outdoor LED

- photovoltaic inverters

- ship lighting

- 5G base stations

- telecommunications systems

INSTALLATION GUIDELINES

- Insert the Screw-Fit vent into the housing with the threads aligned properly and screw into the housing.

- After ensuring that the vent is threaded properly, tighten the vent to 0.6 – 1.0 Nm (5-10 in-lb).

- Optional hex nut is available for M12x1.5 Screw-Fit vents.

- Chamfer recommended for optimal O-Ring seal when wall thickness is suitable.

E-mail:weitaiyan@spider-amoy.com

WhatsApp:18695679892