What is the function of an ePTFE membrane vent?

2022-05-07

Venting is essential to enable the proper functioning of high end technical electronic devices as well as basic every day products. Vents allow pressure to escape, they protect electronics from contaminants entering the product, they aid cooling, help prevent condensation, all of these features helps the correct functioning of your device, maintaining its lifespan.

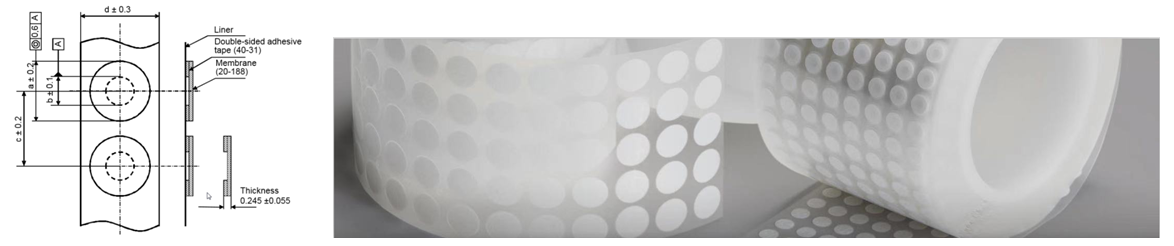

Typically your product is fully sealed, the gaskets all working and when closed nothing gets in or out. This is where the vent is required. Placing a hole in your product then placing one of our adhesive vent patches over that hole keeps the product waterproof and prevents dust and any other contaminants entering. The size of the hole and the number of vents depends on a number of issues. We can assist you to select the best membrane vent material for your device/application.

The membrane vent’s main function is to allow pressure to pass through. In a sealed device, as sunlight hits the device or as the temperature rises, so does the pressure inside the box. This pressure has to escape otherwise constant stress is placed on your product’s seals/gaskets. Conversely as the temperature reduces, so does the pressure, without a vent, the sealed box/device will attempt to suck the outside world into your device. Through time this will damage the product’s seals and potentially create a point of failure for ingress to occur.

Any moisture that builds up within the sealed device as a result of condensation, could affect your product’s electronics. A vent allows that moisture to escape, preventing condensation from forming. This is why is is rare to see condensation in a vehicle headlamp these days unlike the past – as they are all now vented. The moisture can now escape.

Devices with batteries require vents to deal with gassing, to maintain a safe performance of the device.

Tags: Protective Vents